| Unit Price: | USD 800.0000 - 2700.0000 / Set/Sets |

|---|---|

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

Basic Info

Model No.: LDC, LD, LDP, HD

Warranty: 12 Months

Place Of Origin: Henan, China

Brand: DGCrane

Duty Group: M3/M4

Application: Building Material Shops, Machinery Repair Shops

Certificate: ISO, CE, CUTR, SGS, BV

Power Source: 220V~480V

Lifting Mechanism: Wire Rope Hoist/Chain Hoist

Safety: Weight Overload Protection

Paint Color: Custom-sized

Additional Info

Packaging: Electric hoist is packed by plywood crate case, others are packed by non-woven fabrics

Productivity: 1500sets/month

Brand: DGCrane

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 18000 sets/year

Certificate: ISO

HS Code: 84261120

Port: Qingdao Port,Tianjin Port,Shanghai Port

Product Description

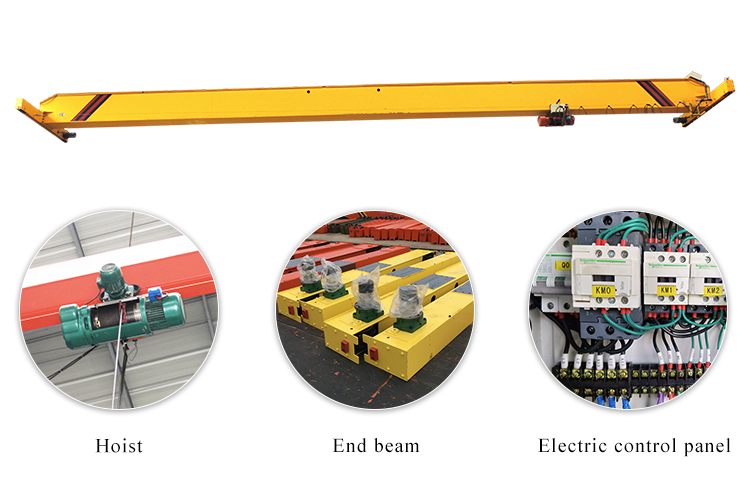

Brief introduction for Henan single girder overhead crane workshop use design

A Single Beam Overhead Crane is an overhead bridge crane that has one bridge girder that supports the trolley and hoist. The trolley and hoist ride on the bottom flange of the bridge girder. The single beam ovehread crane is considered top running when the bridge girder rides on top of the runway beams.

Application: This crane is usually used indoors, such as workshop, plant, stockyard, etc. to lift goods. It is prohibited to use the equipment in the combustible, explosive or corrosive environment.

Low headroom type single girder bridge crane

There are workshop with limited height from bracket to ground, but needs higher lifting height, then we will design the crane with square box girder and low headroom hoist, which will be with higher lifting height.

Suspension type single girder bridge crane

For some workshop, there are concrete beams in the ceiling, but no columns. According practical needs, there needs an overhead crane, so we will suggest suspension type crane which hangs on the concrete beam if the roof can bear the weight enough.

European type single girder bridge crane

For the workshop of high-tech products, or if you have requirement of low noise, the European type crane is recommended.

Side hanging type single girder bridge crane

In some workshop, the column height is limited, but there is much space from column top to ceiling. According to this condition, we will give side hanging type crane with side hanging hoist, which will make the lifting height higher.

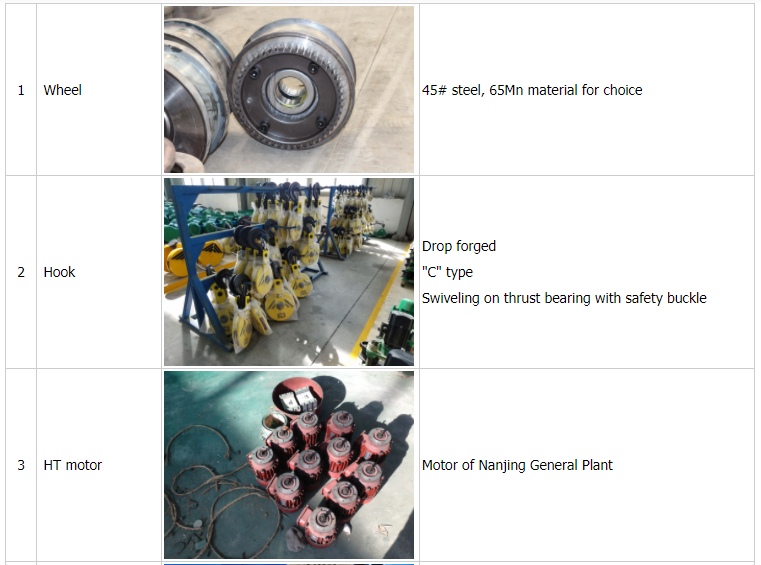

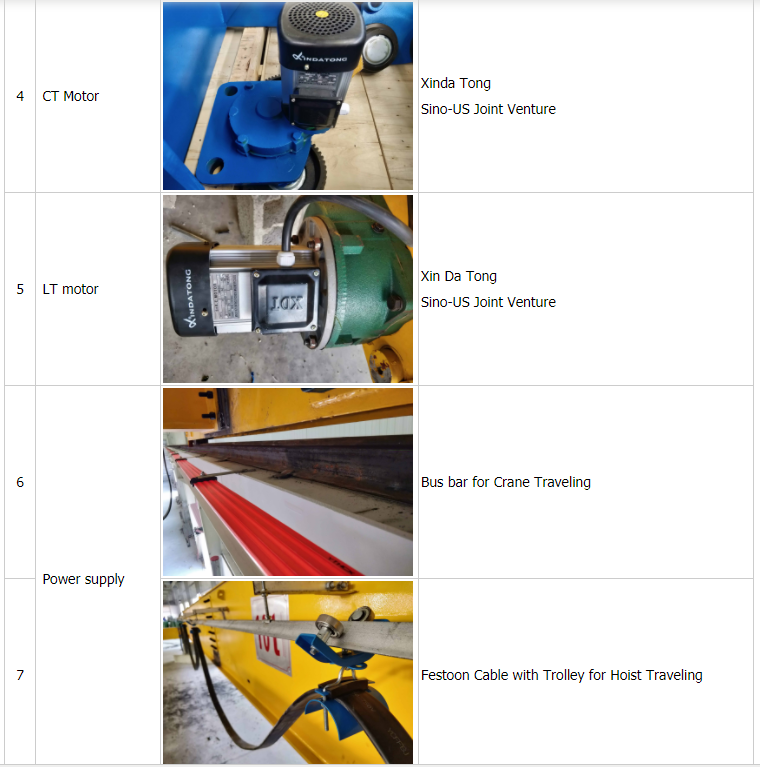

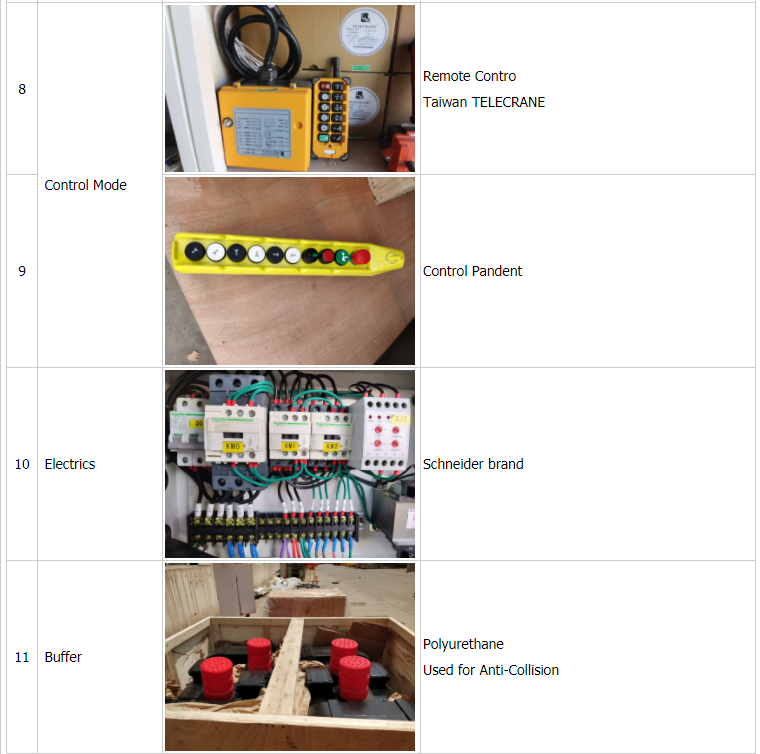

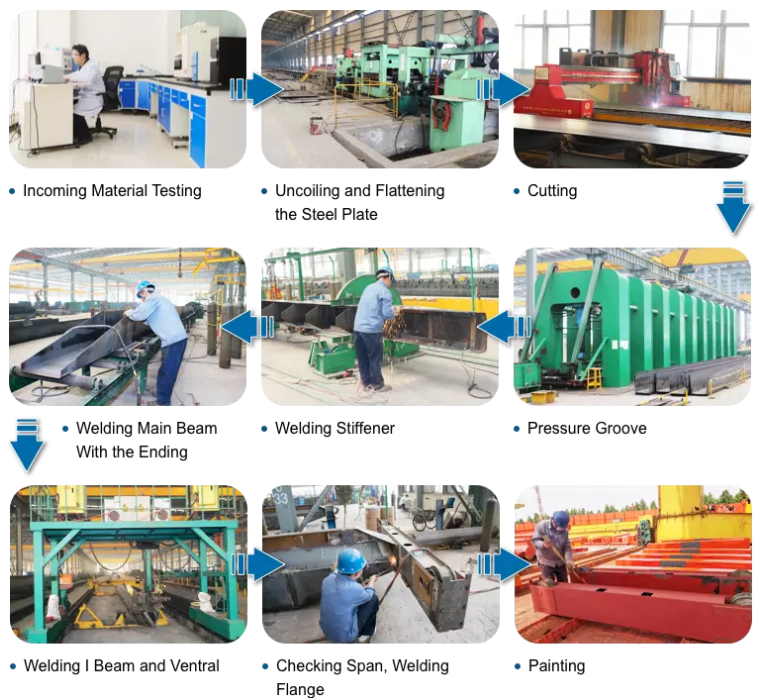

Incoming material

test

Uncoiling

and flattening the steel plate

Every batch of raw materials must be tested when

they enter the factory. We set up a special testing room.It covers non-destructive

inspection room, metallographic analysis and hardness inspection room, mechanics

inspection and chemical inspection room. Testing methods has non-destructive

testing,metallographic analysis, mechanical testing and chemical analysis, mainly

testing and control of the raw materials, crane components, product

After uncoiling, leveling, sizing and shearing,

the required length and width of the flat sheet can be obtained, which can

protect the flat sheet without scars, high shearing accuracy, double palletizing and discharging, high efficiency and speed.

Pressure Groove

According to crane specifications to groove

pressing with different model, and main girder forming at one time can realize that the

U-groove of the whole main girder of single girder crane has no butt weld, thus

reducing stress concentration point, improving the strength and stiffness of the main

girder, and greatly improving the comprehensive bearing capacity of the main

girder.

Welding Stiffener

There is a support which can keep the main girder

be not deformed, and workers can work easily without bending.

Welding main beam with the ending

Welding I beam and ventral

Submerged arc welding (SAW) is a kind of

protective welding with Rohm double gun automatic welding, which has the advantages of

full weld, deep molten pool, beautiful shape and high welding quality. At the same

time, the welding distortion is reduced.

Checking span,welding flange

In production, the hanging plates of the main

girder and the end girder are processed together, punched together, and then knock down

from end beam and weld to the main girder.

Painting

Two-layer primer, two-layer paint

Steel parts

Steel parts are packed in polythene woven cloth, which can prevent

rainwater from directly contacting the crane and protect the painting

Electric parts and hoist

Electric parts are packed by strong plywood crate case, which plays a

protective and moistureproof role.

Basic informations needed of single girder overhead crane

1. Capacity:_ ( max weight of material)

2. Span:_ ( rail center to rail

center)

3. Lifting height:_ ( from ground to

hook)

4. Crane traveling length:_m

5. What goods will the crane lift?

6. Working environment:

7. Speed requirement:

8. Comtrol method: control pendent,

remote control, cabin control ( normally choose controll pendent and remote control)

CONTACT US

XINXIANG DEGONG MACHINERY CO., LTD.

Contact Person: Michael

Phone:86-0373-3876288

Fax:86-0373-3876088

Address: Room 1-1 R&D Building, Torch Industrial Zone, Xinfei Road 1789,Xinxiang,Henan