| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

Basic Info

Model No.: DG

Application: Machinery Accessories

Technology: Casting Or Forging

Material: 42CrMo, 65#steel, 50SiMn, 65Mn, SSQ1R, SAE4140

Heat Treatment: Quenching And Tempering

OEM: Accepted

Brand Name: DGCrane

Packing: Plywood Crate Case

Place Of Origin: Henan, China

Coating: Black Ozide + Rust Proof Oil

Quality Control: UT, MT, X-ray Test, PT

Additional Info

Packaging: The wheels are packed by plywood crate case

Productivity: 1000sets/month

Brand: DGCrane

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 12000 sets/year

Certificate: ISO9001,ISO14001

HS Code: 84314999

Port: Qingdao Port,Tianjin Port,Shanghai Port

Product Description

Brief Introduction for 10t Gantry Crane Wheel 42CrMo Forged Steel Wheel

DGCRANE WHEELS (Crane wheels, Gear wheels, Transfer Cart Wheel, Sheave wheels, Train wheel, Wheel With Gearring, Wheel With Shaft and so on) are widely used in the Crane Manufacturer, The port authority, Transportation, Airlines, Railway locomotive, large-scale construction machinery and so on.

DGCRANE manufactures quality WHEEL to any specification. Each of these in-service factors must be carefully considered before the combination of wheel design, material selection, hardness pattern and heat treating technology is selected. Our wide range of machinery and manufacturing experience, coupled with our dedication to quality, make DGCRANE the right choice for all your WHEELS requirements.

Forged & Casting Crane Wheels are available in a wide range of standard sizes. In addition, crane wheels to meet your special design requirements can be produced in virtually any size, configuration and surface finish condition. We maintain a large inventory of carbon and alloy steels to meet your specific needs.

| Type: | Forging |

| Application: | Crane, trolley, transfer car, heavy duty industry, port crane, steel factory etc. |

| Material: | 4140/SCM440/42CrMo.SSW-Q1R/65#steel, 65Mn, 50SiMn, QT800, ZG35SiMn. |

| Dimension: |

φ250, φ350, φ400, φ500, φ600, φ700, φ800, φ 1000, φ 1200 or as your require |

| Rated loading capacity: |

1~160ton |

| Process: | Forging |

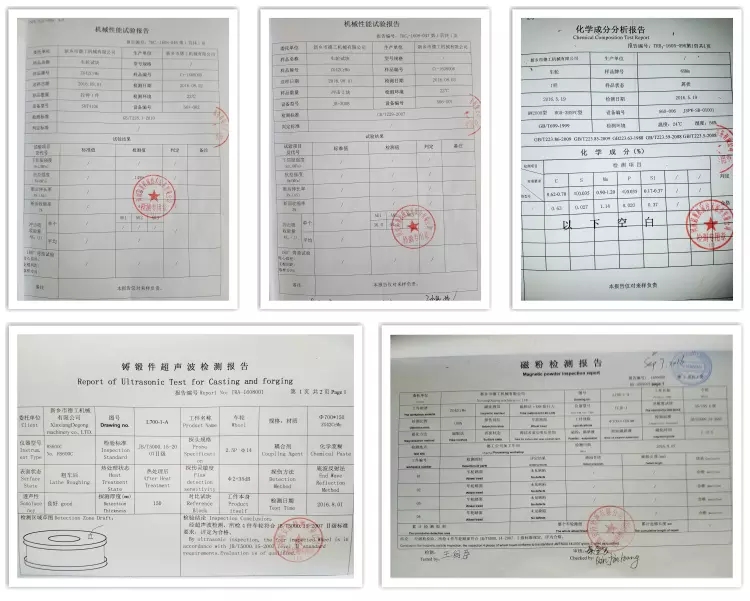

| Quality Control: | UT, MT, RT, PT, chemical composition test, mechanical property test, etc. |

| Heat treatment: | Quenching and tempering |

| Quenching depth: | No less than 20mm. |

| Coating: | Black Ozide + rust proof oil |

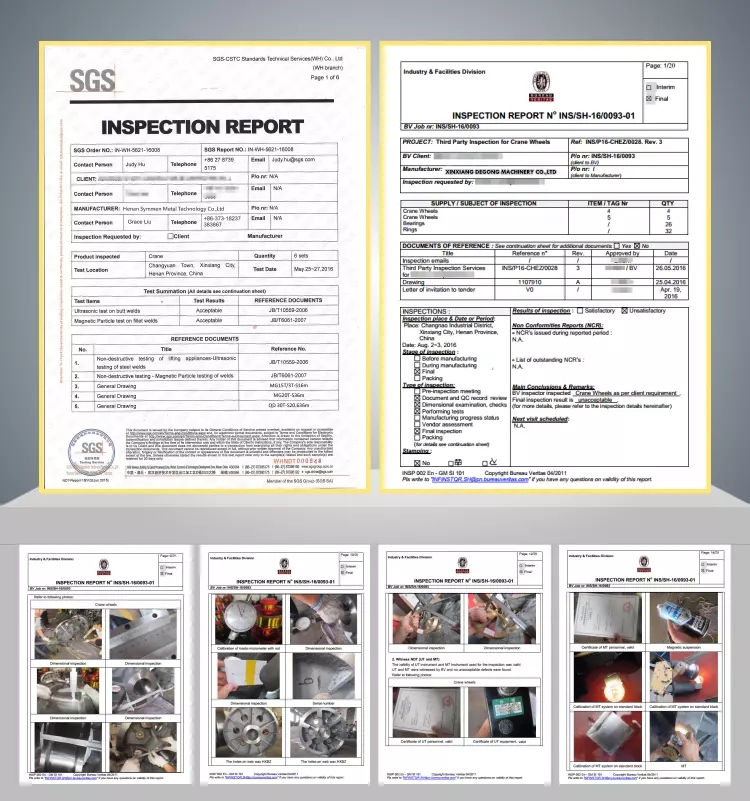

| Inspection: | Besides our in-house inspection, you could also choose a third party inspection. |

| Standard: | ASTM, SAME, DIN, JIS, ISO, BS, API, EN, GOST etc. |

| Certificate: | 1. Raw material certificate(material chemical composition) |

|

|

2. Heat treatment sheet report. |

|

|

3. Dimension inspection report. |

|

|

4. UT/MT test report |

| Packing: | Seaworthy plywood packaged on steel pallets or as customer's request. |

| Delivery date: | 15~30 working days. |

| Competetive advantage: | Quality control and management to the whole produce process, including ingot smelting, forging, heat treatment, machining and strictly final inspection prior to delivery. |

Products Show

About our company

DGCRANE established in 2010, registered capital 200 millions, floor area 300000 square meters and more than 500 workers with 56 engineers of them.

The company has the rich production experience, strong technical force, reliable product quality and advanced production and test equipment, and has advanced processing machines and test equipment totally 300 sets.

Among of the equipment, 24 sets of advanced production equipment like NILES Gear grinding machine of Germany, MAZAK Horizontal and vertical CNC of Japan, AICHELIN Heat treatment product line of Austria, FISCHER Center-hole grinder of Switzerland, microcomputer control tool grinder, etc, and 12 sets of advanced test equipment like Germany ZEISS microscope, SPECTRO spectrograph, Three-dimensional detector, etc.

Raw Material workshopThe company focuses on the design, R&D and fabrication. Moreover, main processes the crane accessories like crane wheel, pulley wheel, etc. Our products involving five kinds with thousands of series and are widely used in the field of lifting, transportation, metallurgy, mine, ship, port etc. Among, the kind of wheels include Special crane wheels, pulley wheel, wheel for transfer cart, Explosion-Proof Wheel, Gear wheel, Crane Wheel Assembly and so on. Finished Wheels warehouseWe have many years of production experience, so it is easier to meet customer demand for processing technology and material. Rich export experience, can make us accurate grasp of wheels for customers' special requirements in different countries. So far, our wheels have been exported to more than 30 countries and regions, like: Russia, Singapore, Sri Lanka, Qatar, Tanzania, Saudi Arabia, Peru, Brazil, Nigeria, the United States, Sweden, Estonia, and so on. Blank WarehouseOther crane parts exports are nearly 60 countries. Many clients from the world famous company and even international famous company, like Italy (IMF) group (the largest supplier of foundry equipment) Elkem etc also chose us. The company gains the Enterprise safety Production Certificate with Class 2 in 2014, and passes the BV Testing, SGS Testing, such as the third party testing and GOST Certificate. |

Mill Testing Certificate For Crane Wheels

Package & Delivery

FAQ

Q: What is your MOQ?

A: We do not have MOQ; we welcome trial order before mass-production. For most of the products, we can send even 1 unit to you, very special requirement or parts customized to be discussed. You could ask us for details.

Q: Do you provide samples and how can I get them?

A: It depends on the specific item you need, we can send it to you by DHL, by Air or By Sea.

Q: How long is your delivery time?

A: Generally it is 15-30 days if the goods are in stock. or it is 25-50 days if the goods are not in stock, it is according to quantity.

Q: What testing form can I get from you?

A: Our inspection equipment has coordinated measuring machine, tensile testing machine, and spectrograph. Except the usual test such as material test, heat treatment, dimensional inspection, we also can do Ultrasonic (UT) testing, Magnetic particle inspection (MT),Mechanical performance test (Tensile test, Impact test, yield strength and so on) according to your requirements.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 40% T/T in advance ,balance before shippment.

For big order, we can accept L/C at sight with good credit banks. For small order, we also can via western union etc.

Q: Which country have your products been exported?

A: We have been exported business for many years and we have lots of customers and agents in the world, our wheels has exported more than 60 countries such as Singapore, Sweden, Spain, Italy, Poland, Norway, Belgium, Estonia Malaysia, South Africa, Canada, America, etc

Q: How long is the warranty of your products? Does your company supply the spare parts?

A: The warranty is one year. We are always glad to provide technical supports and solutions for the whole using life. The warranty period of the consumable and wearing parts is 6 months. And of course we will supply the spare parts for you at lowest cost.

Q: What services can I get from you?

A: 1. We are always here for your needs;

2. You can get catalog, pictures, videos about us;

3. You can get quote from us anytime you need;

4. Customizing services, OEM services, etc.

5. When we confirmed the order, we can design the production drawings for you.

Q: How can i trust your company?

A: 1. With professional design and sales team, we can serve you the perfect solution with lowest cost.

2. Assessed by third party, national patents for all equipment.

3. Welcome to inspect anytime.

CONTACT US

XINXIANG DEGONG MACHINERY CO., LTD.

Contact Person: Michael

Phone:86-0373-3876288

Fax:86-0373-3876088

Address: Room 1-1 R&D Building, Torch Industrial Zone, Xinfei Road 1789,Xinxiang,Henan